Precise inspection of various processing steps in pipe manufacturing is gaining enormous importance. On the one hand, it is important to automate processes, on the other hand, it is indispensable for a cost-efficient production to detect rejects as early as possible.

The requirements on pipe measurements regarding accuracy and fast, process-reliable inspection, up to 100% inspection of the components directly in production, are constantly increasing.

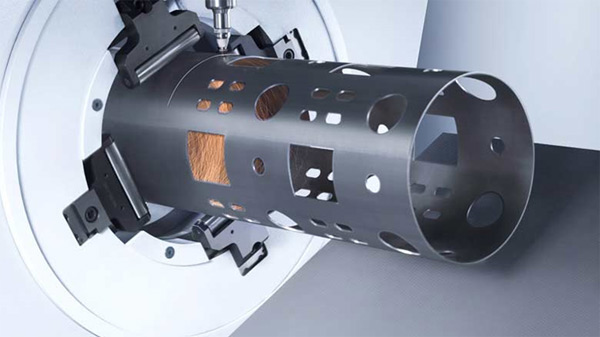

The LOTOS 3D measuring systems are used both for quality inspection of the tube pieces and for process control and defined alignment for the next processing steps.